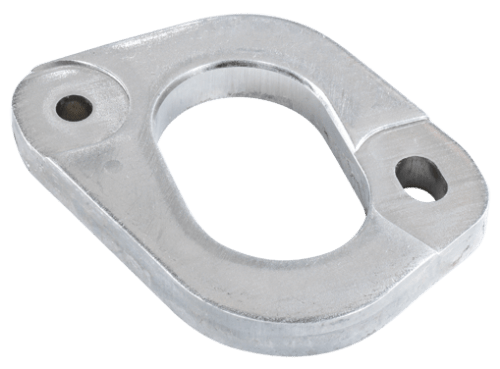

From a small flange for exhaust gas return systems to a single-component head flange for five-cylinder engines, our comprehensive product range covers all conceivable types of flanges and panels.

Flanges and panels.

Flanges and panels business field.

Our flanges and panels.

Case study / Volkswagen AG.

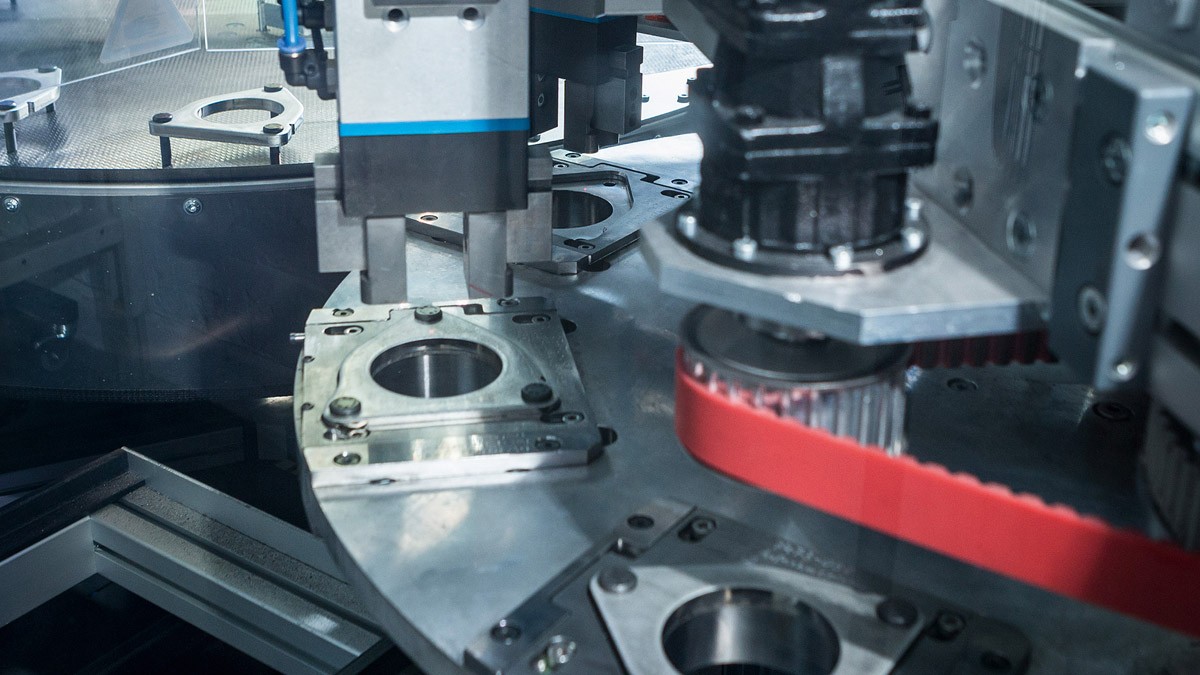

Business field Forming flanges

Case study.

Customer

Volkswagen AG

Product: Forming flanges

Project overview.

Project

Connection joint between turbocharger and exhaust gas system

To dos

Develop manufacturing concept, prototypes, volume production, process monitoring

SOP

2010

Individual parts produced

> 16,000,000 pieces

Project challenge.

- To substitute a forged part

- Material hardening by forming

- Zero-error target

Solution concept.

- Appropriate material cross-sections, machining of just the sealing surface

- Machine concept precisely aligned to the forming flange

- Continual process monitoring by means of structure-borne sound, camera systems and eddy current

Know-how + digitalisation x 16 million parts = zero ppm.

> 16 million

products produced since 2010

32 delivery locations

worldwide

1.4828

Material

0 ppm

Error rate

Case study / Daimler AG.

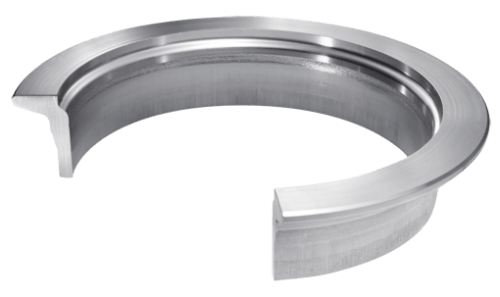

Business field Flanges

Case study.

Customer

Daimler AG

Product: Flanges

Project overview.

Project

Exhaust manifold flanges

To dos

Component optimisation for non-cutting machining

SOP

2012

Individual parts produced

> 16,000,000 pieces

Project challenge.

- Material 1.4301 in sheet-metal thickness of 10 mm

- Drill-hole diameter only 70% of the sheet-metal thickness

- > For cost reasons, no machining outside the sealing surface

Solution concept.

- Multi-step fine blanking tool

- Daisy-chain grinding process with 100% inspection using camera systems

Creativity & force cleverly combined.

> 16 million

products produced between 2014–18

3 delivery locations

worldwide

1.4301

Material

< 10 ppm

Error rate