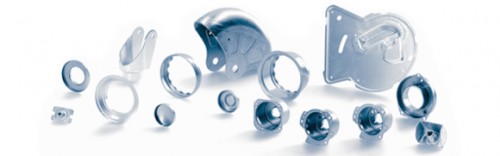

Stamping and forming parts with up to 1,000 tonnes of compressive force, sheet-metal with a thickness ranging from 0.8 to 16 mm – these figures alone illustrate the incredibly wide range of services that our company provides.

We supply our products to discerning customers in the automotive and electrical industry, for vehicle construction as well as to manufacturers of self-service systems located all over the world.

Producing over 30 million flanges and clamps each year, we are one of the leading global companies in the field of exhaust gas technology and cooling systems.